Corlina has been instrumental in helping us achieve our objectives for our Smart Factory, particularly our goals for remote monitoring from Japan.

Can your IIoT data be trusted?

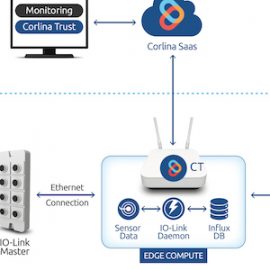

Corlina provides an immutable, time-based record of data integrity for industrial applications.

Winner of the 2020 Security Excellence Award

Device Security & Self-Monitoring

Protect your devices from tampering and unexpected changes with instantaneous notifications of changes in connections, applications, or behavior.

Process Integrity

Continuously track system attributes including operating state, connectivity, and applications operating on your Intel-based Linux OS devices.

Confidence in Business Outcomes

Verify the consistent operation of every device in every location to eliminate data gaps or lost data, ensuring the accuracy of future decisions.

![]()

Latest articles

We were very excited to learn on Friday that the Corlina System of Trust has received a 2019 IoT Evolution Industrial IoT Product of the Year Award from IoT Evolution World, the leading magazine and Web site covering IoT technologies. It’s very exciting when your product receives this type of

In our recent articles, we’ve talked about taking a different approach to embarking on building IIoT capabilities, one that protects organizations from pilot purgatory by focusing on a specific challenge in the manufacturing environment and yielding ROI quickly. It’s not a rip-and-replace method requiring massive investments in new equipment. It’s

Solution Overview Corlina’s brownfield monitoring solution blueprint is intended to enable monitoring and decision-making based on information captured from already-in-place equipment. These existing systems are often implemented on closed architectures and/or closed data buses for reliability reasons, or they may not include any embedded sensors whatsoever. Corlina provides a cost-effective